wft paint test|Wet Film Thickness Combs and Gauges: Your Ultimate Guide : fabrication Wet film thickness (WFT) is the measured thickness of any applied wet paint that is liquid-based. The WFT is measured to assure that the correct amount of coating is being applied to the surface. Mariele&Kevin - link do grupo no telegram. Grupos do Telegram. ThePornDude; Home Mais recentes Mais votados Mais vistos Adicione seu grupo aqui 👉 @Linksparceiros_bot. .

{plog:ftitle_list}

webAssista aos jogos de futebol ao vivo online com o ProTipster, um site que oferece links para streaming de diversas competições e canais. Veja a programação completa dos .

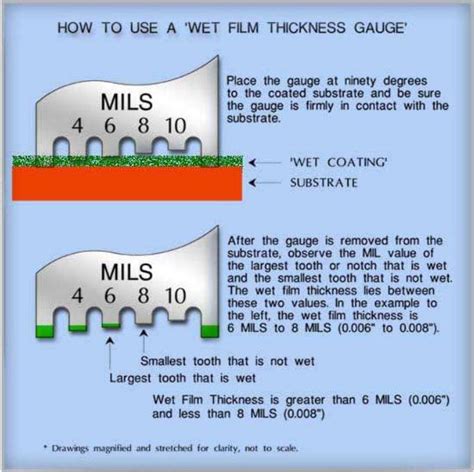

How is WFT measured? Wet film thickness gages are used to monitor the thickness of the applied wet coating to achieve a specified dry film thickness. They measure all types of wet organic coatings, such as paint, varnish, and .Wet Film Thickness (WFT) refers to the depth of a coating measured immediately after application, before drying or curing. Measuring WFT is important to predict the final Dry Film .Wet Film Thickness Gauges are designed to quickly and easily measure the thickness of coatings immediately after they have been applied to a substrate. These gauges are also commonly known as: Combs, MIL Gauges, Step .Wet film thickness (WFT) is the measured thickness of any applied wet paint that is liquid-based. The WFT is measured to assure that the correct amount of coating is being applied to the surface.

Wet film thickness, or WFT, is the measured thickness of any liquid applied coating while it is still wet. A wet film thickness gauge should be used by the applicator, as the coating is being applied, to ensure that the average applied .

This video includes the Theoretical and practical application of Wet film thickness measuring. From this video you can clearly understand; 1- What is WFT .To get the wet film thickness measurements just right, browse our range of wet film thickness measurement tools to find the right one for your project. Find out how to accurately measure the wet film thickness of a coating by using .

There are two methods for testing film thickness - wet film thickness (WFT) measurement and dry film thickness (DFT) measurement. Wet film thickness measurement. As the name suggests, the painter performs this test during the .Wet film thickness (WFT) combs and gauges are measurement tools used to determine the thickness of a coating immediately after it has been applied and before it has had time to dry .

Wet film thickness notched WFT gauge is used to

The gauge may now be read to determine the wet film thickness. The ends of the teeth or notches are visually examined, some will be coated or 'wet' and some will not be coated or 'wet'. The wet film thickness (WFT) of the coating lies .The dry film thickness can be calculated using the ‘solids to liquids’ ratio, also known as the volume solids content. For example: if the paint has a volume solids value of 80% and the wet film thickness is 200 µm, the dry film thickness will be 160 µm (200 µm x 80% = 160 µm). How to measure wet film thickness using a wet film wheel A WFT gauge is used to test the thickness of a liquid-based wet coating and should be used as the coating is being applied to ensure proper measurement of the wet film before there is significant solvent evaporation. In order to ensure the most accurate readings, a DFT gauge is only used once the film has achieved thumbprint hardness.

Wet film thickness (WFT) is the measured thickness of any applied wet paint that is liquid-based. The WFT is measured to assure that the correct amount of coating is being applied to the surface. A wet film thickness gage should be used by the applicator to determine the thickness of the applied film before significant solvent evaporation occurs.

Wet Film Thickness – WFT The Benefits of Accurate Wet Film Thickness Measurement What is Wet Film Thickness? Using a wet film thickness gauge allows you to measure the wet film thickness of your paint or coating with accuracy and precision. This ensures that the coating applied is of the highest quality, providing a smooth

Those that remain above the paint will have no coating on them. The thickness of the paint lies between the value of the shortest tooth to be coated and the adjacent tooth which will be the longest tooth to be uncoated. Some training organisations recommend that the last tooth to be coated (225 um in the picture below) be recorded as the WFT. Learn how to calculate the Wet Film Thickness (WFT) that must be applied to achieve the desired Dry Film Thickness (DFT).The PaintCalc app is used by industr.This being a destructive test, many users test wft gauge on the sample of rectangular panel, measure wet film thickness and control process parameters. . Caltech India also supply disposable plastic WFT gauges for minimum use, simply place the wft gage in the wet paint and note the wet paint thickness, Allow paint to dry and retain for future .Providing quality control paint and coating tools and equipment for testing, measurement, and inspection for the laboratory and field since 1936. +1 (954) 946-9454. Products; Industries; . The Gardco cross hatch paint adhesion test kit is the ideal choice for cross-cut tests. SHOP NOW. PosiTector 6000 Coating Thickness Gages for ALL Metal .

Conforms to ISO 2808, ASTM D4414, AS/NZS 1580.107.3, JIS K 5600-1-7, NF T30-125, US NAVY NSI 009-32 and others The correct paint meter to use depends on the thickness range of the coating, the shape and type of substrate, the cost of the paint meter, and how critical it is to get an accurate measurement. DAVID BEAMISH (1955 – 2019), former President of DeFelsko Corporation, a New York-based manufacturer of hand-held coating inspection instruments sold .The methodology is quite simple and you can easily train your operators to perform the test. If you do not like this suggestion then perhaps you can try to calibrate each coating by comparing its viscosity with its corresponding dry film thickness.WFT Testing. Looking for Wet Film Thickness Gauges? Paul N. Gardner Has Answers. Speak to an Expert Today! We Have the Widest Range of In-Stock Wet Film Testing Products. . For over 80 years, Paul N. Gardner Company has been supplying solutions for paint and coatings testing. Most of our Sales Team has over 20 years of experience and can help .

This revolutionary Gauge will change they way you measure WFT. Free Shipping Over 0 | 1-800-582-4243. Search Login / Register . If none of the numbered notches have paint on them, you will want to move to a lower head. . Many organizations require verification of gauge accuracy at the test site each time a coating thickness gauge is put .Paint A has a volume solids of 50% and a wet film thickness measured at 250μm (10 mils) DFT = 250 x 50% = 125μm (5 mils) Paint B has a volume solids of 70% and the specification requires a dry film thickness of 100µm (4 mils) WFT=DFT/Volume solids=100/0.7= 143µm (5.7 mils)For example: if the paint has a volume solids value of 80% and the wet film thickness is 200 µm, the dry film thickness will be 160 µm (200 µm x 80% = 160 µm). How to measure wet film thickness using a wet film comb. Place a wet film comb down on the surface under test, positioning the comb perpendicular to the substrate. So a DFT of 90 microns using a paint with a volume solid (VS) of 60% we would calculate the following to find the WFT; WFT = 100 x DFT / VS (WFT = 100 x 90 / 60) therefore giving us 150 microns as the Wet Film Thickness (WFT). Dry Film Thickness (DFT)

The problem with spray finishing is that you have to get just the right amount of finish on the surface. Too much, and you might get runs and sags. Too little, and it might dry too fast and create an uneven surface. The way to know if you’re putting on just the right amount — the amount the label on the finish tells you to use — is to use a wet-film thickness gauge.

Wet Film Thickness (WFT) is typically measured using a notched film gage where a rigid metal gage with notched sides and tabs of varying heights is pushed perpendicularly into the coating system. After the gage is removed, the coating thickness is determined to be between the deepest notch with paint adhering to it and the next deepest notch .

Wet Film Thickness Gauges, also recognized as Wet Mil Gauges, WFT Gauges, Combs, Comb Gauges, Mil Gauges, Step Gauges, and Notched Gauges, are specifically designed to swiftly and effortlessly assess paint and coating thickness post-application but before curing. They integrate a set of notches resembling the teeth of a comb.Conforms to ISO 2808, ASTM D4414, AS/NZS 1580.107.3, JIS K 5600-1-7, NF T30-125, US NAVY NSI 009-32 and others. What is a wet film thickness (WFT) and how to use a WFT gauge to ensure proper application of paint coatings. NEPA Remodeling provides cabinet painting & ref.

VIII. WFT AND DFT RELATIONSHIP WFT and DFT Calculations WFT Measurements DFT Measurements 4. Measuring Surface Profiles Nondestructive Testing Gages Coating Thickness –Gage Selection 7.WFT and Holiday Testing Procedures 8. Adhesion & Destructive Testing Procedures Base Metal Reading (BMR) 10. DFT Rules ImmersionPainting CureEvaluation IX.Wet film thickness (WFT) is the measurement of the thickness of an applied paint or coating before it dries. Wet Film thickness is measured using a Wet Film Thickness Gauge. Wet Film Thickness Gauges provide an inexpensive, quick and easy method to measure the thickness of coatings immediately after application. They can be used over a large .

The Wet Film Gauges Plastic ensures the quality control of the paint thickness while the coating is still wet. Supplied in quantities of 200 and give the industrial painter a quick and easy test of the wet film thickness.. They can also be kept as a permanent record of the paint thickness.. All Wet Film Gauges have metric values on the front side of the gauge and imperial values on the back.measured to determine what the applied WFT was. Why is WFT important? Measuring the WFT of a coating enables the applicator to adjust the spray gun speed, number of spray passes and to make spray gun adjustments to ensure sufficient coating is applied to meet the fire testing without over applying which negatively affects your profits. Figure 1.The New Gardco Temper II is a handy new stainless steel tool adhesion test template which allows you to use all the popular crosscut spacings, 1, 1.5, 2, and 3mm, in one unit. +1 (954) 946-9454 Products

rx8 compression test kit

rx8 compression test near me

Adibet.com provides free soccer predictions from european footbal leagues and cups, international matches and competitions.

wft paint test|Wet Film Thickness Combs and Gauges: Your Ultimate Guide